Unlocking the Potential of OEM UL FM Gate Valves: Enhancing Safety and Efficiency Through Advanced Valve Solutions

2025-12-22

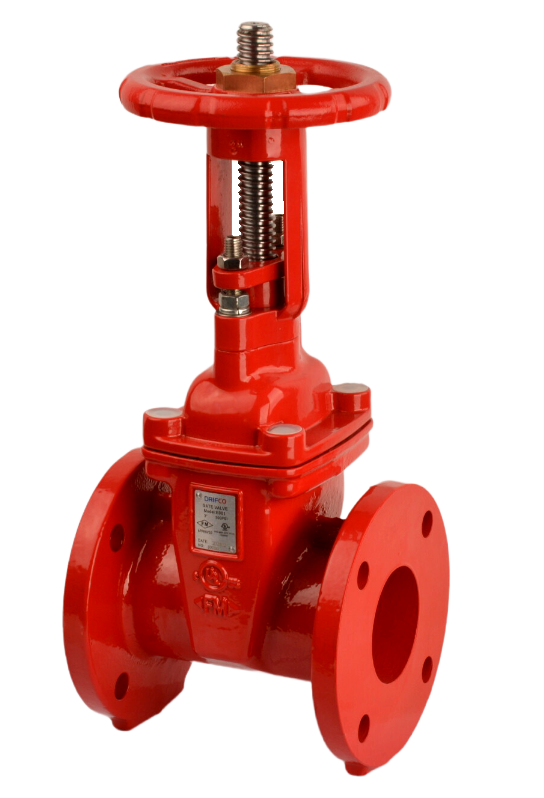

In the world of industrial safety and operational efficiency, OEM UL FM gate valves play a crucial role, yet their full potential often remains untapped. At DRIFCO, we're diving into how advanced valve solutions aren't just about meeting standards—they're about redefining them. This blog explores key innovations and practical insights that enhance both safety protocols and workflow efficiencies, offering a fresh perspective on why upgrading your valve systems with cutting-edge technologies makes a tangible difference. Join us as we uncover the strategies and benefits that set superior solutions apart, tailored for professionals seeking reliable, high-performance outcomes.

Innovative Features of OEM UL FM Gate Valves for Enhanced Safety

OEM UL FM gate valves prioritize safety through advanced design elements that meet stringent industry standards, such as UL and FM approvals. These valves incorporate robust materials and precision engineering to ensure reliable performance in critical applications. For instance, features like reinforced body construction and corrosion-resistant coatings minimize the risk of leaks or failures, enhancing operational safety in environments prone to hazards like fire or chemical exposure. This focus on durable components sets them apart by providing long-term protection and peace of mind.

Differentiating from standard valves, OEM UL FM gate valves often include smart monitoring capabilities, such as integrated sensors for real-time pressure and temperature tracking. This innovation allows for proactive maintenance and early detection of potential issues, reducing downtime and preventing accidents. By combining traditional mechanical reliability with modern technology, these valves offer a unique blend of safety and efficiency that adapts to evolving industrial needs, making them a standout choice for safety-conscious installations.

The enhanced safety is further supported by customizable features, like flexible sealing options and user-friendly interfaces for easy operation. These valves are designed with ergonomics in mind, simplifying maintenance tasks and reducing human error during adjustments. By tailoring solutions to specific risk scenarios, they provide a competitive edge in safety applications, ensuring compliance while offering practical benefits that go beyond basic certification requirements.

Boosting Operational Efficiency with Advanced Valve Technology

OEM UL FM gate valves prioritize safety through advanced design elements that meet stringent industry standards, such as UL and FM approvals. These valves incorporate robust materials and precision engineering to ensure reliable performance in critical applications. For instance, features like reinforced body construction and corrosion-resistant coatings minimize the risk of leaks or failures, enhancing operational safety in environments prone to hazards like fire or chemical exposure. This focus on durable components sets them apart by providing long-term protection and peace of mind.

Differentiating from standard valves, OEM UL FM gate valves often include smart monitoring capabilities, such as integrated sensors for real-time pressure and temperature tracking. This innovation allows for proactive maintenance and early detection of potential issues, reducing downtime and preventing accidents. By combining traditional mechanical reliability with modern technology, these valves offer a unique blend of safety and efficiency that adapts to evolving industrial needs, making them a standout choice for safety-conscious installations.

The enhanced safety is further supported by customizable features, like flexible sealing options and user-friendly interfaces for easy operation. These valves are designed with ergonomics in mind, simplifying maintenance tasks and reducing human error during adjustments. By tailoring solutions to specific risk scenarios, they provide a competitive edge in safety applications, ensuring compliance while offering practical benefits that go beyond basic certification requirements.

In today's fast-paced industrial landscape, advanced valve technology plays a pivotal role in enhancing operational efficiency by streamlining control processes and minimizing downtime. These cutting-edge valves, equipped with smart features like IoT connectivity and real-time monitoring, allow for precise flow regulation and automatic adjustments, leading to significant energy savings and reduced maintenance needs. By integrating such systems, companies can optimize resource usage and achieve smoother, more reliable operations across various sectors, from oil and gas to water treatment.

Beyond mere automation, advanced valve technology introduces innovative materials and designs that boost longevity and resilience in harsh environments. For instance, valves made from corrosion-resistant alloys or with self-cleaning mechanisms can withstand extreme pressures and temperatures, extending their service life and cutting replacement costs. This translates to fewer interruptions in production cycles and a lower overall environmental footprint, as more durable components mean less waste and energy consumption over time.

What truly sets advanced valve systems apart is their ability to adapt and learn from operational data, offering predictive maintenance capabilities. By analyzing patterns in valve performance, these technologies can forecast potential failures before they occur, enabling proactive repairs that prevent costly breakdowns. This not only enhances safety by reducing the risk of unexpected malfunctions but also empowers businesses to plan maintenance schedules strategically, thereby maximizing uptime and driving continuous improvement in efficiency.

Meeting Industry Standards: UL and FM Certifications Explained

OEM UL FM gate valves prioritize safety through advanced design elements that meet stringent industry standards, such as UL and FM approvals. These valves incorporate robust materials and precision engineering to ensure reliable performance in critical applications. For instance, features like reinforced body construction and corrosion-resistant coatings minimize the risk of leaks or failures, enhancing operational safety in environments prone to hazards like fire or chemical exposure. This focus on durable components sets them apart by providing long-term protection and peace of mind.

Differentiating from standard valves, OEM UL FM gate valves often include smart monitoring capabilities, such as integrated sensors for real-time pressure and temperature tracking. This innovation allows for proactive maintenance and early detection of potential issues, reducing downtime and preventing accidents. By combining traditional mechanical reliability with modern technology, these valves offer a unique blend of safety and efficiency that adapts to evolving industrial needs, making them a standout choice for safety-conscious installations.

The enhanced safety is further supported by customizable features, like flexible sealing options and user-friendly interfaces for easy operation. These valves are designed with ergonomics in mind, simplifying maintenance tasks and reducing human error during adjustments. By tailoring solutions to specific risk scenarios, they provide a competitive edge in safety applications, ensuring compliance while offering practical benefits that go beyond basic certification requirements.

In today's fast-paced industrial landscape, advanced valve technology plays a pivotal role in enhancing operational efficiency by streamlining control processes and minimizing downtime. These cutting-edge valves, equipped with smart features like IoT connectivity and real-time monitoring, allow for precise flow regulation and automatic adjustments, leading to significant energy savings and reduced maintenance needs. By integrating such systems, companies can optimize resource usage and achieve smoother, more reliable operations across various sectors, from oil and gas to water treatment.

Beyond mere automation, advanced valve technology introduces innovative materials and designs that boost longevity and resilience in harsh environments. For instance, valves made from corrosion-resistant alloys or with self-cleaning mechanisms can withstand extreme pressures and temperatures, extending their service life and cutting replacement costs. This translates to fewer interruptions in production cycles and a lower overall environmental footprint, as more durable components mean less waste and energy consumption over time.

What truly sets advanced valve systems apart is their ability to adapt and learn from operational data, offering predictive maintenance capabilities. By analyzing patterns in valve performance, these technologies can forecast potential failures before they occur, enabling proactive repairs that prevent costly breakdowns. This not only enhances safety by reducing the risk of unexpected malfunctions but also empowers businesses to plan maintenance schedules strategically, thereby maximizing uptime and driving continuous improvement in efficiency.

When it comes to safety and reliability in the industrial world, UL and FM certifications aren't just optional extras—they're the bedrock of trust. These certifications are awarded by two of the most respected independent testing and certification organizations globally: UL (Underwriters Laboratories) and FM (Factory Mutual). Both have carved out unique niches over decades, with UL often focusing on electrical and product safety, and FM specializing in property loss prevention, particularly for high-hazard industries. Earning these marks means a product or system has undergone rigorous testing against established standards, such as UL's ANSI/UL standards or FM's Approval Standards, which are developed through extensive industry collaboration and research.

What truly sets these certifications apart from generic approvals is their proactive approach to risk management. Unlike some basic compliance checks, UL and FM don't just test for initial safety; they emphasize ongoing performance and durability. For example, FM certifications often involve evaluations under extreme conditions, like fire or explosion scenarios, ensuring equipment can withstand real-world hazards. Similarly, UL certifications might include long-term reliability tests to predict product lifespan and failure modes. This depth of scrutiny helps manufacturers not only meet regulatory requirements but also build products that enhance operational safety and reduce liability risks, making them invaluable for sectors like manufacturing, energy, and construction.

In practice, navigating UL and FM certifications requires a strategic mindset. It's not merely about ticking boxes; it's about aligning product design with industry-specific benchmarks. Companies often engage with these organizations early in the development process to avoid costly redesigns later. The benefits extend beyond compliance—certified products can command higher market trust, streamline insurance approvals, and even open doors to global markets where these standards are recognized. Ultimately, UL and FM certifications are more than symbols on a label; they represent a commitment to excellence that resonates with safety-conscious buyers and regulatory bodies alike.

Custom Valve Solutions for Diverse Industrial Applications

OEM UL FM gate valves prioritize safety through advanced design elements that meet stringent industry standards, such as UL and FM approvals. These valves incorporate robust materials and precision engineering to ensure reliable performance in critical applications. For instance, features like reinforced body construction and corrosion-resistant coatings minimize the risk of leaks or failures, enhancing operational safety in environments prone to hazards like fire or chemical exposure. This focus on durable components sets them apart by providing long-term protection and peace of mind.

Differentiating from standard valves, OEM UL FM gate valves often include smart monitoring capabilities, such as integrated sensors for real-time pressure and temperature tracking. This innovation allows for proactive maintenance and early detection of potential issues, reducing downtime and preventing accidents. By combining traditional mechanical reliability with modern technology, these valves offer a unique blend of safety and efficiency that adapts to evolving industrial needs, making them a standout choice for safety-conscious installations.

The enhanced safety is further supported by customizable features, like flexible sealing options and user-friendly interfaces for easy operation. These valves are designed with ergonomics in mind, simplifying maintenance tasks and reducing human error during adjustments. By tailoring solutions to specific risk scenarios, they provide a competitive edge in safety applications, ensuring compliance while offering practical benefits that go beyond basic certification requirements.

In today's fast-paced industrial landscape, advanced valve technology plays a pivotal role in enhancing operational efficiency by streamlining control processes and minimizing downtime. These cutting-edge valves, equipped with smart features like IoT connectivity and real-time monitoring, allow for precise flow regulation and automatic adjustments, leading to significant energy savings and reduced maintenance needs. By integrating such systems, companies can optimize resource usage and achieve smoother, more reliable operations across various sectors, from oil and gas to water treatment.

Beyond mere automation, advanced valve technology introduces innovative materials and designs that boost longevity and resilience in harsh environments. For instance, valves made from corrosion-resistant alloys or with self-cleaning mechanisms can withstand extreme pressures and temperatures, extending their service life and cutting replacement costs. This translates to fewer interruptions in production cycles and a lower overall environmental footprint, as more durable components mean less waste and energy consumption over time.

What truly sets advanced valve systems apart is their ability to adapt and learn from operational data, offering predictive maintenance capabilities. By analyzing patterns in valve performance, these technologies can forecast potential failures before they occur, enabling proactive repairs that prevent costly breakdowns. This not only enhances safety by reducing the risk of unexpected malfunctions but also empowers businesses to plan maintenance schedules strategically, thereby maximizing uptime and driving continuous improvement in efficiency.

When it comes to safety and reliability in the industrial world, UL and FM certifications aren't just optional extras—they're the bedrock of trust. These certifications are awarded by two of the most respected independent testing and certification organizations globally: UL (Underwriters Laboratories) and FM (Factory Mutual). Both have carved out unique niches over decades, with UL often focusing on electrical and product safety, and FM specializing in property loss prevention, particularly for high-hazard industries. Earning these marks means a product or system has undergone rigorous testing against established standards, such as UL's ANSI/UL standards or FM's Approval Standards, which are developed through extensive industry collaboration and research.

What truly sets these certifications apart from generic approvals is their proactive approach to risk management. Unlike some basic compliance checks, UL and FM don't just test for initial safety; they emphasize ongoing performance and durability. For example, FM certifications often involve evaluations under extreme conditions, like fire or explosion scenarios, ensuring equipment can withstand real-world hazards. Similarly, UL certifications might include long-term reliability tests to predict product lifespan and failure modes. This depth of scrutiny helps manufacturers not only meet regulatory requirements but also build products that enhance operational safety and reduce liability risks, making them invaluable for sectors like manufacturing, energy, and construction.

In practice, navigating UL and FM certifications requires a strategic mindset. It's not merely about ticking boxes; it's about aligning product design with industry-specific benchmarks. Companies often engage with these organizations early in the development process to avoid costly redesigns later. The benefits extend beyond compliance—certified products can command higher market trust, streamline insurance approvals, and even open doors to global markets where these standards are recognized. Ultimately, UL and FM certifications are more than symbols on a label; they represent a commitment to excellence that resonates with safety-conscious buyers and regulatory bodies alike.

Industries are as varied as the challenges they face, demanding more than just off-the-shelf components. Custom valve solutions step in to address unique operational needs, from handling extreme temperatures to managing corrosive fluids. By tailoring valve designs to specific applications, companies can boost system reliability and minimize downtime.

Whether it's oil and gas, chemical processing, or power generation, custom valves adapt to industry-specific pressures and flow requirements. These bespoke designs ensure valves perform optimally under varied conditions, enhancing safety and operational efficiency without sticking to generic standards.

With advancements in materials and engineering, custom valve solutions offer flexibility and precision. They empower industries to tackle complex scenarios, such as controlling volatile substances or integrating with automated systems, paving the way for smarter and more resilient industrial setups.

Optimizing Maintenance and Longevity in Fluid Control Systems

OEM UL FM gate valves prioritize safety through advanced design elements that meet stringent industry standards, such as UL and FM approvals. These valves incorporate robust materials and precision engineering to ensure reliable performance in critical applications. For instance, features like reinforced body construction and corrosion-resistant coatings minimize the risk of leaks or failures, enhancing operational safety in environments prone to hazards like fire or chemical exposure. This focus on durable components sets them apart by providing long-term protection and peace of mind.

Differentiating from standard valves, OEM UL FM gate valves often include smart monitoring capabilities, such as integrated sensors for real-time pressure and temperature tracking. This innovation allows for proactive maintenance and early detection of potential issues, reducing downtime and preventing accidents. By combining traditional mechanical reliability with modern technology, these valves offer a unique blend of safety and efficiency that adapts to evolving industrial needs, making them a standout choice for safety-conscious installations.

The enhanced safety is further supported by customizable features, like flexible sealing options and user-friendly interfaces for easy operation. These valves are designed with ergonomics in mind, simplifying maintenance tasks and reducing human error during adjustments. By tailoring solutions to specific risk scenarios, they provide a competitive edge in safety applications, ensuring compliance while offering practical benefits that go beyond basic certification requirements.

In today's fast-paced industrial landscape, advanced valve technology plays a pivotal role in enhancing operational efficiency by streamlining control processes and minimizing downtime. These cutting-edge valves, equipped with smart features like IoT connectivity and real-time monitoring, allow for precise flow regulation and automatic adjustments, leading to significant energy savings and reduced maintenance needs. By integrating such systems, companies can optimize resource usage and achieve smoother, more reliable operations across various sectors, from oil and gas to water treatment.

Beyond mere automation, advanced valve technology introduces innovative materials and designs that boost longevity and resilience in harsh environments. For instance, valves made from corrosion-resistant alloys or with self-cleaning mechanisms can withstand extreme pressures and temperatures, extending their service life and cutting replacement costs. This translates to fewer interruptions in production cycles and a lower overall environmental footprint, as more durable components mean less waste and energy consumption over time.

What truly sets advanced valve systems apart is their ability to adapt and learn from operational data, offering predictive maintenance capabilities. By analyzing patterns in valve performance, these technologies can forecast potential failures before they occur, enabling proactive repairs that prevent costly breakdowns. This not only enhances safety by reducing the risk of unexpected malfunctions but also empowers businesses to plan maintenance schedules strategically, thereby maximizing uptime and driving continuous improvement in efficiency.

When it comes to safety and reliability in the industrial world, UL and FM certifications aren't just optional extras—they're the bedrock of trust. These certifications are awarded by two of the most respected independent testing and certification organizations globally: UL (Underwriters Laboratories) and FM (Factory Mutual). Both have carved out unique niches over decades, with UL often focusing on electrical and product safety, and FM specializing in property loss prevention, particularly for high-hazard industries. Earning these marks means a product or system has undergone rigorous testing against established standards, such as UL's ANSI/UL standards or FM's Approval Standards, which are developed through extensive industry collaboration and research.

What truly sets these certifications apart from generic approvals is their proactive approach to risk management. Unlike some basic compliance checks, UL and FM don't just test for initial safety; they emphasize ongoing performance and durability. For example, FM certifications often involve evaluations under extreme conditions, like fire or explosion scenarios, ensuring equipment can withstand real-world hazards. Similarly, UL certifications might include long-term reliability tests to predict product lifespan and failure modes. This depth of scrutiny helps manufacturers not only meet regulatory requirements but also build products that enhance operational safety and reduce liability risks, making them invaluable for sectors like manufacturing, energy, and construction.

In practice, navigating UL and FM certifications requires a strategic mindset. It's not merely about ticking boxes; it's about aligning product design with industry-specific benchmarks. Companies often engage with these organizations early in the development process to avoid costly redesigns later. The benefits extend beyond compliance—certified products can command higher market trust, streamline insurance approvals, and even open doors to global markets where these standards are recognized. Ultimately, UL and FM certifications are more than symbols on a label; they represent a commitment to excellence that resonates with safety-conscious buyers and regulatory bodies alike.

Industries are as varied as the challenges they face, demanding more than just off-the-shelf components. Custom valve solutions step in to address unique operational needs, from handling extreme temperatures to managing corrosive fluids. By tailoring valve designs to specific applications, companies can boost system reliability and minimize downtime.

Whether it's oil and gas, chemical processing, or power generation, custom valves adapt to industry-specific pressures and flow requirements. These bespoke designs ensure valves perform optimally under varied conditions, enhancing safety and operational efficiency without sticking to generic standards.

With advancements in materials and engineering, custom valve solutions offer flexibility and precision. They empower industries to tackle complex scenarios, such as controlling volatile substances or integrating with automated systems, paving the way for smarter and more resilient industrial setups.

Keeping fluid control systems running smoothly over the long haul isn't just about fixing things when they break—it's about smart, proactive strategies that prevent issues before they start. In industries from manufacturing to water treatment, these systems are the unsung heroes that keep operations flowing. To optimize maintenance and boost longevity, many experts are shifting from reactive repairs to predictive approaches using advanced sensors and data analytics. By monitoring parameters like pressure, flow rates, and temperature in real-time, potential failures can be spotted early, reducing downtime and extending equipment life. This shift not only saves money but also enhances system reliability, ensuring fluids move exactly where they're needed without hiccups.

Beyond high-tech tools, simple yet often overlooked practices play a crucial role in longevity. Regular inspections and scheduled upkeep, tailored to the specific type of fluid and environmental conditions, help combat corrosion, wear, and contamination. For instance, in hydraulic systems, using the right fluid grade and maintaining cleanliness can prevent component degradation that leads to costly replacements. Employee training is another key factor: when staff understand how to operate systems gently and spot early warning signs, human error decreases, and maintenance becomes more effective. It's a blend of technology and hands-on care that transforms a basic upkeep routine into a longevity-boosting strategy.

What truly sets apart top-performing fluid control systems is their adaptability and integration into broader operational goals. Instead of treating maintenance as a standalone task, successful organizations align it with efficiency and sustainability initiatives. For example, optimizing valve adjustments and pump speeds can reduce energy consumption while prolonging equipment life. Case studies from the oil and gas sector show that systems designed with modular components allow for easier upgrades and repairs, minimizing disruptions. By viewing maintenance as an investment in continuous improvement, companies not only extend system lifespan but also gain a competitive edge through enhanced performance and reduced environmental impact.

Strategic Advantages in Risk Mitigation and Cost Savings

OEM UL FM gate valves prioritize safety through advanced design elements that meet stringent industry standards, such as UL and FM approvals. These valves incorporate robust materials and precision engineering to ensure reliable performance in critical applications. For instance, features like reinforced body construction and corrosion-resistant coatings minimize the risk of leaks or failures, enhancing operational safety in environments prone to hazards like fire or chemical exposure. This focus on durable components sets them apart by providing long-term protection and peace of mind.

Differentiating from standard valves, OEM UL FM gate valves often include smart monitoring capabilities, such as integrated sensors for real-time pressure and temperature tracking. This innovation allows for proactive maintenance and early detection of potential issues, reducing downtime and preventing accidents. By combining traditional mechanical reliability with modern technology, these valves offer a unique blend of safety and efficiency that adapts to evolving industrial needs, making them a standout choice for safety-conscious installations.

The enhanced safety is further supported by customizable features, like flexible sealing options and user-friendly interfaces for easy operation. These valves are designed with ergonomics in mind, simplifying maintenance tasks and reducing human error during adjustments. By tailoring solutions to specific risk scenarios, they provide a competitive edge in safety applications, ensuring compliance while offering practical benefits that go beyond basic certification requirements.

In today's fast-paced industrial landscape, advanced valve technology plays a pivotal role in enhancing operational efficiency by streamlining control processes and minimizing downtime. These cutting-edge valves, equipped with smart features like IoT connectivity and real-time monitoring, allow for precise flow regulation and automatic adjustments, leading to significant energy savings and reduced maintenance needs. By integrating such systems, companies can optimize resource usage and achieve smoother, more reliable operations across various sectors, from oil and gas to water treatment.

Beyond mere automation, advanced valve technology introduces innovative materials and designs that boost longevity and resilience in harsh environments. For instance, valves made from corrosion-resistant alloys or with self-cleaning mechanisms can withstand extreme pressures and temperatures, extending their service life and cutting replacement costs. This translates to fewer interruptions in production cycles and a lower overall environmental footprint, as more durable components mean less waste and energy consumption over time.

What truly sets advanced valve systems apart is their ability to adapt and learn from operational data, offering predictive maintenance capabilities. By analyzing patterns in valve performance, these technologies can forecast potential failures before they occur, enabling proactive repairs that prevent costly breakdowns. This not only enhances safety by reducing the risk of unexpected malfunctions but also empowers businesses to plan maintenance schedules strategically, thereby maximizing uptime and driving continuous improvement in efficiency.

When it comes to safety and reliability in the industrial world, UL and FM certifications aren't just optional extras—they're the bedrock of trust. These certifications are awarded by two of the most respected independent testing and certification organizations globally: UL (Underwriters Laboratories) and FM (Factory Mutual). Both have carved out unique niches over decades, with UL often focusing on electrical and product safety, and FM specializing in property loss prevention, particularly for high-hazard industries. Earning these marks means a product or system has undergone rigorous testing against established standards, such as UL's ANSI/UL standards or FM's Approval Standards, which are developed through extensive industry collaboration and research.

What truly sets these certifications apart from generic approvals is their proactive approach to risk management. Unlike some basic compliance checks, UL and FM don't just test for initial safety; they emphasize ongoing performance and durability. For example, FM certifications often involve evaluations under extreme conditions, like fire or explosion scenarios, ensuring equipment can withstand real-world hazards. Similarly, UL certifications might include long-term reliability tests to predict product lifespan and failure modes. This depth of scrutiny helps manufacturers not only meet regulatory requirements but also build products that enhance operational safety and reduce liability risks, making them invaluable for sectors like manufacturing, energy, and construction.

In practice, navigating UL and FM certifications requires a strategic mindset. It's not merely about ticking boxes; it's about aligning product design with industry-specific benchmarks. Companies often engage with these organizations early in the development process to avoid costly redesigns later. The benefits extend beyond compliance—certified products can command higher market trust, streamline insurance approvals, and even open doors to global markets where these standards are recognized. Ultimately, UL and FM certifications are more than symbols on a label; they represent a commitment to excellence that resonates with safety-conscious buyers and regulatory bodies alike.

Industries are as varied as the challenges they face, demanding more than just off-the-shelf components. Custom valve solutions step in to address unique operational needs, from handling extreme temperatures to managing corrosive fluids. By tailoring valve designs to specific applications, companies can boost system reliability and minimize downtime.

Whether it's oil and gas, chemical processing, or power generation, custom valves adapt to industry-specific pressures and flow requirements. These bespoke designs ensure valves perform optimally under varied conditions, enhancing safety and operational efficiency without sticking to generic standards.

With advancements in materials and engineering, custom valve solutions offer flexibility and precision. They empower industries to tackle complex scenarios, such as controlling volatile substances or integrating with automated systems, paving the way for smarter and more resilient industrial setups.

Keeping fluid control systems running smoothly over the long haul isn't just about fixing things when they break—it's about smart, proactive strategies that prevent issues before they start. In industries from manufacturing to water treatment, these systems are the unsung heroes that keep operations flowing. To optimize maintenance and boost longevity, many experts are shifting from reactive repairs to predictive approaches using advanced sensors and data analytics. By monitoring parameters like pressure, flow rates, and temperature in real-time, potential failures can be spotted early, reducing downtime and extending equipment life. This shift not only saves money but also enhances system reliability, ensuring fluids move exactly where they're needed without hiccups.

Beyond high-tech tools, simple yet often overlooked practices play a crucial role in longevity. Regular inspections and scheduled upkeep, tailored to the specific type of fluid and environmental conditions, help combat corrosion, wear, and contamination. For instance, in hydraulic systems, using the right fluid grade and maintaining cleanliness can prevent component degradation that leads to costly replacements. Employee training is another key factor: when staff understand how to operate systems gently and spot early warning signs, human error decreases, and maintenance becomes more effective. It's a blend of technology and hands-on care that transforms a basic upkeep routine into a longevity-boosting strategy.

What truly sets apart top-performing fluid control systems is their adaptability and integration into broader operational goals. Instead of treating maintenance as a standalone task, successful organizations align it with efficiency and sustainability initiatives. For example, optimizing valve adjustments and pump speeds can reduce energy consumption while prolonging equipment life. Case studies from the oil and gas sector show that systems designed with modular components allow for easier upgrades and repairs, minimizing disruptions. By viewing maintenance as an investment in continuous improvement, companies not only extend system lifespan but also gain a competitive edge through enhanced performance and reduced environmental impact.

When it comes to mitigating risks and cutting costs, strategic advantages often stem from proactive and integrated approaches. For instance, by embedding risk assessment into every phase of project development, organizations can identify potential hurdles early, reducing the likelihood of costly delays or failures. This foresight not only safeguards resources but also enhances overall efficiency, creating a ripple effect that streamlines operations and boosts profitability. It's about turning potential threats into opportunities for optimization.

Another key aspect is the use of data-driven decision-making. By leveraging analytics and real-time monitoring, companies can anticipate market shifts and operational inefficiencies, allowing for timely adjustments that prevent financial losses. This dynamic strategy goes beyond traditional cost-cutting measures, fostering a culture of continuous improvement where savings are achieved without compromising quality or innovation. It's a balanced approach that prioritizes long-term stability over short-term gains.

Moreover, fostering collaboration across departments can unveil hidden synergies that drive down expenses while fortifying risk defenses. When teams share insights and resources, they can implement cohesive solutions that address multiple challenges simultaneously, such as integrating sustainability practices that reduce environmental risks and lower operational costs. This holistic perspective ensures that advantages in risk and cost management are not isolated but interwoven, delivering compounded benefits that set a company apart in competitive landscapes.

FAQ

OEM UL FM gate valves are specifically designed with dual certifications from Underwriters Laboratories (UL) and Factory Mutual (FM), ensuring they meet rigorous fire safety and performance standards. Unlike standard valves, they incorporate advanced sealing technologies and durable materials that enhance leak resistance and longevity under extreme conditions.

By integrating UL and FM certifications, these gate valves provide reliable fire protection and operational safety. Their robust construction minimizes the risk of valve failure during emergencies, such as fires or high-pressure incidents, thereby protecting personnel, equipment, and facilities from potential hazards.

These valves optimize efficiency through features like smoother operation, reduced maintenance needs, and compatibility with automated systems. Their precise control over fluid flow helps minimize energy loss and downtime, leading to more consistent and cost-effective industrial processes.

UL and FM certifications are critical for applications in high-risk environments like chemical plants, oil refineries, and power generation facilities. They verify that the valves can withstand fire exposure, maintain integrity under stress, and comply with industry regulations, ensuring dependable performance in safety-critical scenarios.

Recent innovations include the use of corrosion-resistant alloys, enhanced stem designs for better torque control, and improved sealing mechanisms like resilient seats. These advancements extend valve lifespan, reduce leakage risks, and adapt to varying operational demands without compromising safety.

Businesses should assess their current valve specifications and consult with manufacturers to ensure compatibility. Proper installation, regular maintenance schedules, and staff training on valve operation can help leverage the full benefits, such as enhanced safety protocols and reduced long-term operational costs.

Challenges may include higher upfront costs and the need for specialized installation. These can be mitigated by considering the long-term savings from reduced maintenance and improved safety, partnering with experienced suppliers for technical support, and conducting thorough pilot tests before full-scale deployment.

Future trends likely focus on smart valve technologies with IoT integration for real-time monitoring, further material advancements for eco-friendliness, and designs that enhance adaptability to diverse industrial environments, pushing the boundaries of safety and efficiency in valve solutions.

Conclusion

The exploration of OEM UL FM gate valves reveals how innovative features fundamentally enhance safety in fluid control systems. These valves are engineered with advanced sealing mechanisms and durable materials that prevent leaks under extreme pressures, directly addressing critical safety concerns in industries like chemical processing and oil refining. The UL and FM certifications aren't just badges but rigorous standards ensuring reliability through comprehensive testing for fire resistance and performance consistency. By integrating these certified components, operations can mitigate risks of equipment failure and hazardous incidents, creating a safer working environment. This focus on safety is complemented by custom solutions tailored for diverse applications, from water treatment to pharmaceutical manufacturing, ensuring each valve meets specific operational demands without compromising protection.

Beyond safety, OEM UL FM gate valves significantly boost operational efficiency through advanced valve technology. Their design minimizes friction and wear, leading to smoother operation and reduced energy consumption in fluid transport systems. This efficiency translates into tangible cost savings by lowering maintenance needs and extending the valve's lifespan, as highlighted by optimized maintenance strategies that include predictive analytics and easy-access components. Strategically, these advantages help industries save on downtime and replacement costs while enhancing overall system performance. By unlocking the potential of these valves, companies not only comply with stringent industry standards but also achieve a competitive edge through improved reliability, reduced operational expenses, and a stronger focus on sustainable, long-term fluid management solutions.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com