Maximizing Safety & Efficiency: The Ultimate Guide to Best UL FM Gate Valves for Fire Protection Systems

2025-12-22

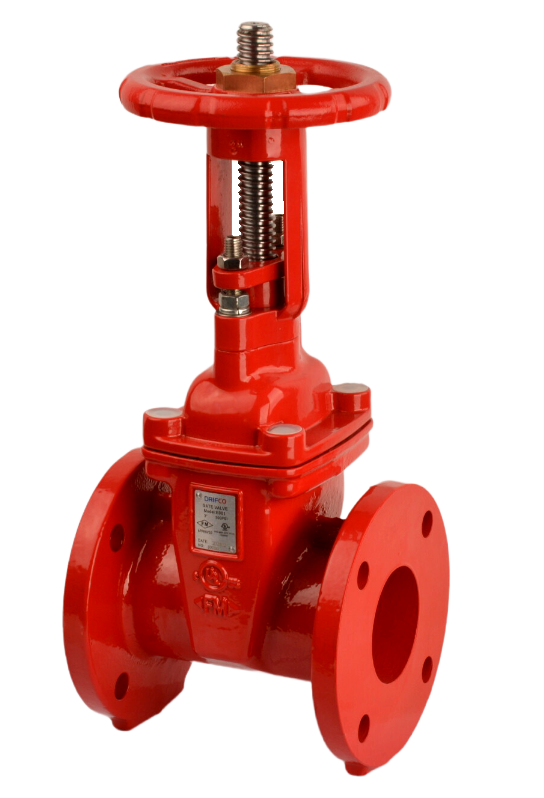

When it comes to fire protection systems, every choice matters. The valves you select could determine the difference between a minor incident and a catastrophic loss. In this guide, we delve into the world of UL FM gate valves, uncovering what makes them not just compliant, but truly exceptional for safety and efficiency. Are you confident your current setup maximizes both? Enter DRIFCO, a name synonymous with reliability in fire safety engineering. Join us as we explore how DRIFCO's innovative solutions set the benchmark, ensuring your systems are not only up to code but ahead of the curve. Get ready to transform your approach—this is where safety meets smart design.

Essential Safety Features of UL FM Gate Valves

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate Valves

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate ValvesKey Efficiency Factors in Fire Protection Gate Valves

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate ValvesWhen it comes to fire protection systems, gate valves play a critical role in ensuring rapid and reliable flow control during emergencies. Efficiency in these valves isn't just about opening and closing; it revolves around factors like ease of operation under high-pressure conditions, minimal resistance to water flow, and quick response times. For instance, a well-designed gate valve should allow firefighters to activate the system with minimal effort, reducing delays that could prove costly in a fire scenario.

Durability and material selection significantly impact efficiency, too. Valves made from corrosion-resistant materials like bronze or stainless steel maintain their functionality over time, even in harsh environments. This reduces maintenance needs and ensures they're always ready for action. Additionally, features like a non-rising stem design can prevent obstruction and allow for smoother operation in tight spaces, making them more practical for real-world installations.

Beyond the physical aspects, efficiency ties into how these valves integrate with modern fire protection systems. Smart valves equipped with sensors can provide real-time monitoring, alerting maintenance teams to potential issues before they fail. This proactive approach minimizes downtime and enhances overall system reliability, ensuring that when a fire strikes, every component performs flawlessly to protect lives and property.

How to Choose the Right UL FM Gate Valve for Your System

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate ValvesWhen it comes to fire protection systems, gate valves play a critical role in ensuring rapid and reliable flow control during emergencies. Efficiency in these valves isn't just about opening and closing; it revolves around factors like ease of operation under high-pressure conditions, minimal resistance to water flow, and quick response times. For instance, a well-designed gate valve should allow firefighters to activate the system with minimal effort, reducing delays that could prove costly in a fire scenario.

Durability and material selection significantly impact efficiency, too. Valves made from corrosion-resistant materials like bronze or stainless steel maintain their functionality over time, even in harsh environments. This reduces maintenance needs and ensures they're always ready for action. Additionally, features like a non-rising stem design can prevent obstruction and allow for smoother operation in tight spaces, making them more practical for real-world installations.

Beyond the physical aspects, efficiency ties into how these valves integrate with modern fire protection systems. Smart valves equipped with sensors can provide real-time monitoring, alerting maintenance teams to potential issues before they fail. This proactive approach minimizes downtime and enhances overall system reliability, ensuring that when a fire strikes, every component performs flawlessly to protect lives and property.

Navigating the selection of a UL FM gate valve for your system can be tricky if you're not sure what to look for. It's not just about picking a valve; it's about understanding how it fits into your overall safety and performance requirements. Start by assessing your system's specific needs, such as the type of fluid, pressure ratings, and environmental conditions. Don't just go by generic specifications—dive into the details to ensure compatibility and reliability.

You'll want to check for certifications like UL (Underwriters Laboratories) and FM (Factory Mutual) approvals, which are crucial for compliance and safety in various industries. Look beyond the basic labels to see how these certifications apply to your application. For instance, some valves might be UL listed but not FM approved for certain uses, so verify both to avoid costly mistakes. Consider factors like material construction, such as cast iron or stainless steel, based on corrosion resistance and durability needs.

To stand out from standard recommendations, think about long-term maintenance and ease of operation. A well-chosen valve should be easy to install, operate smoothly, and require minimal upkeep. Consider options with features like non-rising stems or gear operators if manual control is a priority. Don't overlook supplier support—reputable vendors often provide valuable insights and after-sales service. By focusing on these tailored aspects, you can select a valve that not only meets safety standards but also enhances system efficiency and longevity.

Benefits of Using UL FM Gate Valves in Fire Protection

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate ValvesWhen it comes to fire protection systems, gate valves play a critical role in ensuring rapid and reliable flow control during emergencies. Efficiency in these valves isn't just about opening and closing; it revolves around factors like ease of operation under high-pressure conditions, minimal resistance to water flow, and quick response times. For instance, a well-designed gate valve should allow firefighters to activate the system with minimal effort, reducing delays that could prove costly in a fire scenario.

Durability and material selection significantly impact efficiency, too. Valves made from corrosion-resistant materials like bronze or stainless steel maintain their functionality over time, even in harsh environments. This reduces maintenance needs and ensures they're always ready for action. Additionally, features like a non-rising stem design can prevent obstruction and allow for smoother operation in tight spaces, making them more practical for real-world installations.

Beyond the physical aspects, efficiency ties into how these valves integrate with modern fire protection systems. Smart valves equipped with sensors can provide real-time monitoring, alerting maintenance teams to potential issues before they fail. This proactive approach minimizes downtime and enhances overall system reliability, ensuring that when a fire strikes, every component performs flawlessly to protect lives and property.

Navigating the selection of a UL FM gate valve for your system can be tricky if you're not sure what to look for. It's not just about picking a valve; it's about understanding how it fits into your overall safety and performance requirements. Start by assessing your system's specific needs, such as the type of fluid, pressure ratings, and environmental conditions. Don't just go by generic specifications—dive into the details to ensure compatibility and reliability.

You'll want to check for certifications like UL (Underwriters Laboratories) and FM (Factory Mutual) approvals, which are crucial for compliance and safety in various industries. Look beyond the basic labels to see how these certifications apply to your application. For instance, some valves might be UL listed but not FM approved for certain uses, so verify both to avoid costly mistakes. Consider factors like material construction, such as cast iron or stainless steel, based on corrosion resistance and durability needs.

To stand out from standard recommendations, think about long-term maintenance and ease of operation. A well-chosen valve should be easy to install, operate smoothly, and require minimal upkeep. Consider options with features like non-rising stems or gear operators if manual control is a priority. Don't overlook supplier support—reputable vendors often provide valuable insights and after-sales service. By focusing on these tailored aspects, you can select a valve that not only meets safety standards but also enhances system efficiency and longevity.

When it comes to fire protection systems, the reliability of every component can't be overstated, and UL FM gate valves play a crucial role in ensuring that. These valves are specifically designed and certified to meet rigorous standards set by Underwriters Laboratories (UL) and FM Approvals, which means they've been tested for performance under fire conditions. Unlike generic valves, they offer superior leak-tight sealing and durability, which is essential in high-pressure water or foam systems where any failure could compromise firefighting efforts. This certification isn't just a badge; it's a guarantee that the valve will function when it matters most, helping protect lives and property by maintaining system integrity during emergencies.

Another key advantage of using UL FM gate valves is their operational efficiency, which sets them apart from other options on the market. These valves feature a smooth, full-port design that minimizes flow restriction, allowing water or fire suppressants to move quickly and effectively through the system. This reduces pressure drops and ensures that sprinklers or hoses deliver the necessary volume to combat fires without delay. In practice, this means faster response times in critical situations, giving firefighters an edge. Plus, their robust construction, often with materials like ductile iron or stainless steel, resists corrosion and wear, even in harsh environments, leading to lower maintenance needs and longer service life compared to non-certified alternatives.

Beyond performance and efficiency, UL FM gate valves bring peace of mind through enhanced safety and compliance. In many regions, building codes and insurance requirements mandate the use of certified components in fire protection systems, and these valves help meet those standards effortlessly. Their approval ensures they've undergone strict testing for factors like pressure ratings, fatigue resistance, and fire exposure, reducing the risk of malfunctions that could lead to costly downtime or legal liabilities. By integrating these valves, facility managers can simplify inspections and audits, as inspectors recognize the UL FM mark as a sign of quality and reliability. This not only boosts overall system confidence but also underscores a commitment to proactive safety measures, making them a smart investment for any fire-prone setting.

Common Challenges and Solutions in Gate Valve Applications

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate ValvesWhen it comes to fire protection systems, gate valves play a critical role in ensuring rapid and reliable flow control during emergencies. Efficiency in these valves isn't just about opening and closing; it revolves around factors like ease of operation under high-pressure conditions, minimal resistance to water flow, and quick response times. For instance, a well-designed gate valve should allow firefighters to activate the system with minimal effort, reducing delays that could prove costly in a fire scenario.

Durability and material selection significantly impact efficiency, too. Valves made from corrosion-resistant materials like bronze or stainless steel maintain their functionality over time, even in harsh environments. This reduces maintenance needs and ensures they're always ready for action. Additionally, features like a non-rising stem design can prevent obstruction and allow for smoother operation in tight spaces, making them more practical for real-world installations.

Beyond the physical aspects, efficiency ties into how these valves integrate with modern fire protection systems. Smart valves equipped with sensors can provide real-time monitoring, alerting maintenance teams to potential issues before they fail. This proactive approach minimizes downtime and enhances overall system reliability, ensuring that when a fire strikes, every component performs flawlessly to protect lives and property.

Navigating the selection of a UL FM gate valve for your system can be tricky if you're not sure what to look for. It's not just about picking a valve; it's about understanding how it fits into your overall safety and performance requirements. Start by assessing your system's specific needs, such as the type of fluid, pressure ratings, and environmental conditions. Don't just go by generic specifications—dive into the details to ensure compatibility and reliability.

You'll want to check for certifications like UL (Underwriters Laboratories) and FM (Factory Mutual) approvals, which are crucial for compliance and safety in various industries. Look beyond the basic labels to see how these certifications apply to your application. For instance, some valves might be UL listed but not FM approved for certain uses, so verify both to avoid costly mistakes. Consider factors like material construction, such as cast iron or stainless steel, based on corrosion resistance and durability needs.

To stand out from standard recommendations, think about long-term maintenance and ease of operation. A well-chosen valve should be easy to install, operate smoothly, and require minimal upkeep. Consider options with features like non-rising stems or gear operators if manual control is a priority. Don't overlook supplier support—reputable vendors often provide valuable insights and after-sales service. By focusing on these tailored aspects, you can select a valve that not only meets safety standards but also enhances system efficiency and longevity.

When it comes to fire protection systems, the reliability of every component can't be overstated, and UL FM gate valves play a crucial role in ensuring that. These valves are specifically designed and certified to meet rigorous standards set by Underwriters Laboratories (UL) and FM Approvals, which means they've been tested for performance under fire conditions. Unlike generic valves, they offer superior leak-tight sealing and durability, which is essential in high-pressure water or foam systems where any failure could compromise firefighting efforts. This certification isn't just a badge; it's a guarantee that the valve will function when it matters most, helping protect lives and property by maintaining system integrity during emergencies.

Another key advantage of using UL FM gate valves is their operational efficiency, which sets them apart from other options on the market. These valves feature a smooth, full-port design that minimizes flow restriction, allowing water or fire suppressants to move quickly and effectively through the system. This reduces pressure drops and ensures that sprinklers or hoses deliver the necessary volume to combat fires without delay. In practice, this means faster response times in critical situations, giving firefighters an edge. Plus, their robust construction, often with materials like ductile iron or stainless steel, resists corrosion and wear, even in harsh environments, leading to lower maintenance needs and longer service life compared to non-certified alternatives.

Beyond performance and efficiency, UL FM gate valves bring peace of mind through enhanced safety and compliance. In many regions, building codes and insurance requirements mandate the use of certified components in fire protection systems, and these valves help meet those standards effortlessly. Their approval ensures they've undergone strict testing for factors like pressure ratings, fatigue resistance, and fire exposure, reducing the risk of malfunctions that could lead to costly downtime or legal liabilities. By integrating these valves, facility managers can simplify inspections and audits, as inspectors recognize the UL FM mark as a sign of quality and reliability. This not only boosts overall system confidence but also underscores a commitment to proactive safety measures, making them a smart investment for any fire-prone setting.

One of the most frequent issues with gate valves in industrial settings is the problem of leakage, often stemming from wear on the disc or seat over time. This isn't just a minor inconvenience—it can lead to significant fluid loss, contamination, or even safety hazards in critical applications like oil pipelines or chemical processing plants. To tackle this, many operators are now turning to advanced materials like hardened stainless steel or ceramic coatings for the disc and seat, which dramatically extend service life and maintain a tighter seal under pressure. Regular maintenance schedules that include inspection and replacement of these components before failure occurs can also prevent costly downtime and environmental risks.

Another challenge that crops up, especially in older installations, is the tendency for gate valves to stick or become difficult to operate after periods of inactivity. This often happens due to corrosion buildup or debris accumulation in the valve body, making it hard to fully open or close the disc. A practical solution here is to implement routine flushing procedures with compatible fluids to clear out contaminants. For new designs, opting for valves with anti-corrosion features like epoxy coatings or using lubricated designs can make a world of difference, ensuring smoother operation even in harsh environments like marine or mining applications.

Beyond these operational hurdles, gate valves sometimes face criticism for their slow opening and closing times, which might not suit systems requiring rapid flow control. In response, manufacturers have innovated with quick-acting gate valves that use gear mechanisms or hydraulic actuators to speed up the process, making them more suitable for emergency shutdown scenarios or automated processes. Additionally, integrating smart sensors into valves can provide real-time data on position and flow, allowing for predictive maintenance and better overall system efficiency without the guesswork.

Future Trends in Fire Protection Valve Technology

When it comes to fire safety in industrial settings, UL FM gate valves play a pivotal role, offering reliable shut-off capabilities that are rigorously tested to meet both UL and FM Global standards. These valves are engineered with features like fire-tested designs to withstand extreme temperatures, ensuring they remain operational during a fire to control hazardous fluid flow. Manufacturers often incorporate robust construction materials, such as ductile iron or stainless steel, and enhanced sealing mechanisms to prevent leaks under pressure, making them indispensable in high-risk environments like chemical plants or refineries.

Beyond basic functionality, advanced safety elements include anti-static devices that reduce the risk of spark ignition and low-temperature ratings for use in cold climates. The valves undergo stringent certification processes, including fire endurance and seat leakage tests, to validate their performance in emergency scenarios. This dual certification by UL and FM provides an extra layer of assurance, as it combines electrical safety standards with fire protection expertise, ensuring comprehensive coverage for critical applications.

In practice, proper installation and regular maintenance are key to maximizing these safety features. Inspection routines often focus on checking for wear in the gate and seats, confirming the integrity of fire seals, and testing manual or automated actuators. By prioritizing these aspects, facilities can leverage UL FM gate valves not just as regulatory compliance tools, but as proactive safeguards that enhance overall operational resilience and minimize downtime during incidents.

Key Efficiency Factors in Fire Protection Gate ValvesWhen it comes to fire protection systems, gate valves play a critical role in ensuring rapid and reliable flow control during emergencies. Efficiency in these valves isn't just about opening and closing; it revolves around factors like ease of operation under high-pressure conditions, minimal resistance to water flow, and quick response times. For instance, a well-designed gate valve should allow firefighters to activate the system with minimal effort, reducing delays that could prove costly in a fire scenario.

Durability and material selection significantly impact efficiency, too. Valves made from corrosion-resistant materials like bronze or stainless steel maintain their functionality over time, even in harsh environments. This reduces maintenance needs and ensures they're always ready for action. Additionally, features like a non-rising stem design can prevent obstruction and allow for smoother operation in tight spaces, making them more practical for real-world installations.

Beyond the physical aspects, efficiency ties into how these valves integrate with modern fire protection systems. Smart valves equipped with sensors can provide real-time monitoring, alerting maintenance teams to potential issues before they fail. This proactive approach minimizes downtime and enhances overall system reliability, ensuring that when a fire strikes, every component performs flawlessly to protect lives and property.

Navigating the selection of a UL FM gate valve for your system can be tricky if you're not sure what to look for. It's not just about picking a valve; it's about understanding how it fits into your overall safety and performance requirements. Start by assessing your system's specific needs, such as the type of fluid, pressure ratings, and environmental conditions. Don't just go by generic specifications—dive into the details to ensure compatibility and reliability.

You'll want to check for certifications like UL (Underwriters Laboratories) and FM (Factory Mutual) approvals, which are crucial for compliance and safety in various industries. Look beyond the basic labels to see how these certifications apply to your application. For instance, some valves might be UL listed but not FM approved for certain uses, so verify both to avoid costly mistakes. Consider factors like material construction, such as cast iron or stainless steel, based on corrosion resistance and durability needs.

To stand out from standard recommendations, think about long-term maintenance and ease of operation. A well-chosen valve should be easy to install, operate smoothly, and require minimal upkeep. Consider options with features like non-rising stems or gear operators if manual control is a priority. Don't overlook supplier support—reputable vendors often provide valuable insights and after-sales service. By focusing on these tailored aspects, you can select a valve that not only meets safety standards but also enhances system efficiency and longevity.

When it comes to fire protection systems, the reliability of every component can't be overstated, and UL FM gate valves play a crucial role in ensuring that. These valves are specifically designed and certified to meet rigorous standards set by Underwriters Laboratories (UL) and FM Approvals, which means they've been tested for performance under fire conditions. Unlike generic valves, they offer superior leak-tight sealing and durability, which is essential in high-pressure water or foam systems where any failure could compromise firefighting efforts. This certification isn't just a badge; it's a guarantee that the valve will function when it matters most, helping protect lives and property by maintaining system integrity during emergencies.

Another key advantage of using UL FM gate valves is their operational efficiency, which sets them apart from other options on the market. These valves feature a smooth, full-port design that minimizes flow restriction, allowing water or fire suppressants to move quickly and effectively through the system. This reduces pressure drops and ensures that sprinklers or hoses deliver the necessary volume to combat fires without delay. In practice, this means faster response times in critical situations, giving firefighters an edge. Plus, their robust construction, often with materials like ductile iron or stainless steel, resists corrosion and wear, even in harsh environments, leading to lower maintenance needs and longer service life compared to non-certified alternatives.

Beyond performance and efficiency, UL FM gate valves bring peace of mind through enhanced safety and compliance. In many regions, building codes and insurance requirements mandate the use of certified components in fire protection systems, and these valves help meet those standards effortlessly. Their approval ensures they've undergone strict testing for factors like pressure ratings, fatigue resistance, and fire exposure, reducing the risk of malfunctions that could lead to costly downtime or legal liabilities. By integrating these valves, facility managers can simplify inspections and audits, as inspectors recognize the UL FM mark as a sign of quality and reliability. This not only boosts overall system confidence but also underscores a commitment to proactive safety measures, making them a smart investment for any fire-prone setting.

One of the most frequent issues with gate valves in industrial settings is the problem of leakage, often stemming from wear on the disc or seat over time. This isn't just a minor inconvenience—it can lead to significant fluid loss, contamination, or even safety hazards in critical applications like oil pipelines or chemical processing plants. To tackle this, many operators are now turning to advanced materials like hardened stainless steel or ceramic coatings for the disc and seat, which dramatically extend service life and maintain a tighter seal under pressure. Regular maintenance schedules that include inspection and replacement of these components before failure occurs can also prevent costly downtime and environmental risks.

Another challenge that crops up, especially in older installations, is the tendency for gate valves to stick or become difficult to operate after periods of inactivity. This often happens due to corrosion buildup or debris accumulation in the valve body, making it hard to fully open or close the disc. A practical solution here is to implement routine flushing procedures with compatible fluids to clear out contaminants. For new designs, opting for valves with anti-corrosion features like epoxy coatings or using lubricated designs can make a world of difference, ensuring smoother operation even in harsh environments like marine or mining applications.

Beyond these operational hurdles, gate valves sometimes face criticism for their slow opening and closing times, which might not suit systems requiring rapid flow control. In response, manufacturers have innovated with quick-acting gate valves that use gear mechanisms or hydraulic actuators to speed up the process, making them more suitable for emergency shutdown scenarios or automated processes. Additionally, integrating smart sensors into valves can provide real-time data on position and flow, allowing for predictive maintenance and better overall system efficiency without the guesswork.

As building designs evolve to incorporate more advanced materials and automation, the fire protection industry is moving beyond traditional valve systems. We're seeing innovations like self-diagnostic valves that can detect wear or blockages in real-time, reducing the need for manual inspections. Additionally, lighter and more durable materials are being introduced to improve installation flexibility and longevity in harsh environments. These advancements not only enhance reliability but also cut down on maintenance costs over time.

Another key trend is the integration of fire protection valves with smart building systems. Valves are now being designed to communicate with central monitoring platforms, allowing for immediate alerts during emergencies and better coordination with sprinkler systems. This connectivity enables predictive maintenance, where data analytics can forecast potential failures before they occur. It's a shift from reactive to proactive safety management, ensuring that protection systems are always in optimal condition.

Environmental sustainability is also shaping the future of valve technology. Manufacturers are focusing on developing water-efficient valves that minimize waste during fire suppression, while still meeting stringent safety standards. Innovations include valves that adjust water flow based on fire intensity, reducing unnecessary water usage. Combined with eco-friendly materials, these systems aim to protect both property and the planet, reflecting a growing emphasis on green building practices in fire safety.

FAQ

UL FM certification is crucial because it ensures the valve meets rigorous safety and performance standards. Specifically, it verifies that the gate valve can withstand high-pressure demands during fire emergencies while maintaining reliability over time. This dual certification from UL and FM (Factory Mutual) signals to engineers and installers that the valve has been tested for durability, leak resistance, and operational efficiency under severe conditions, reducing the risk of failure when lives and property are at stake.

These valves enhance safety by incorporating design features that prevent common failure points. For instance, they often use robust materials like bronze or stainless steel to resist corrosion and wear, along with precision-machined seats to ensure a tight seal. This minimizes leaks that could compromise water flow during a fire. Additionally, their tested reliability means they're less likely to jam or malfunction under stress, providing consistent control over water supply in critical moments.

UL FM gate valves boost efficiency through improved flow characteristics and reduced maintenance needs. Their designs typically allow for full-port openings, which minimize pressure drops and ensure maximum water delivery. This can lead to faster response times in fire scenarios. Moreover, their certified durability means fewer inspections and replacements over the system's lifespan, saving time and costs. In contrast, non-certified valves might require more frequent checks and are prone to inefficiencies like flow restrictions or early degradation.

They are highly recommended for high-risk or critical environments where reliability is paramount. This includes commercial buildings like hospitals and schools, industrial facilities with flammable materials, and high-rise constructions. In these applications, the valves are often used in main water supply lines, sprinkler systems, and standpipe systems to control water flow. Their certification makes them a top choice for meeting strict building codes and insurance requirements, ensuring compliance and enhanced protection.

Selection should focus on factors such as pressure rating, material compatibility, and size. Start by assessing the system's maximum operating pressure and temperature to choose a valve with an appropriate rating. Consider the environment—for corrosive settings, stainless steel valves might be best. Size is critical too; ensure the valve matches the pipe diameter to avoid flow issues. Consulting with a fire protection specialist can help tailor the choice to the project's unique needs, balancing safety with budget constraints.

Regular maintenance is key to longevity. Conduct periodic visual inspections for signs of corrosion, leaks, or damage, and test the valve's operation annually to ensure it opens and closes smoothly. Lubricate the stem as recommended by the manufacturer to prevent seizing. Keep the area around the valve clear of debris to avoid obstructions. Documenting these checks helps track performance over time, and following the manufacturer's guidelines ensures the valve remains in optimal condition for emergency use.

Conclusion

UL FM gate valves for fire protection systems combine essential safety features like UL/FM certifications, robust construction with materials such as bronze or ductile iron, and reliable sealing mechanisms to prevent leaks and ensure operational integrity during emergencies. These valves also incorporate efficiency factors, including low-pressure drop design, smooth operation through features like non-rising stems, and corrosion resistance, which enhance system performance and reduce maintenance needs. By integrating these elements, users can maximize both safety and efficiency, selecting valves that meet specific application requirements while adhering to industry standards.

Choosing the right UL FM gate valve involves evaluating system parameters such as pressure ratings, size compatibility, and environmental conditions, while considering benefits like enhanced durability and compliance with regulations. Common challenges, such as valve sticking or corrosion, are addressed through proper installation, regular maintenance, and advanced coatings. Future trends in fire protection technology point toward smart valves with IoT connectivity for real-time monitoring and automated diagnostics, as well as sustainable materials and improved designs for greater resilience. This guide serves as a comprehensive resource for optimizing safety and efficiency through informed valve selection and proactive management.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com